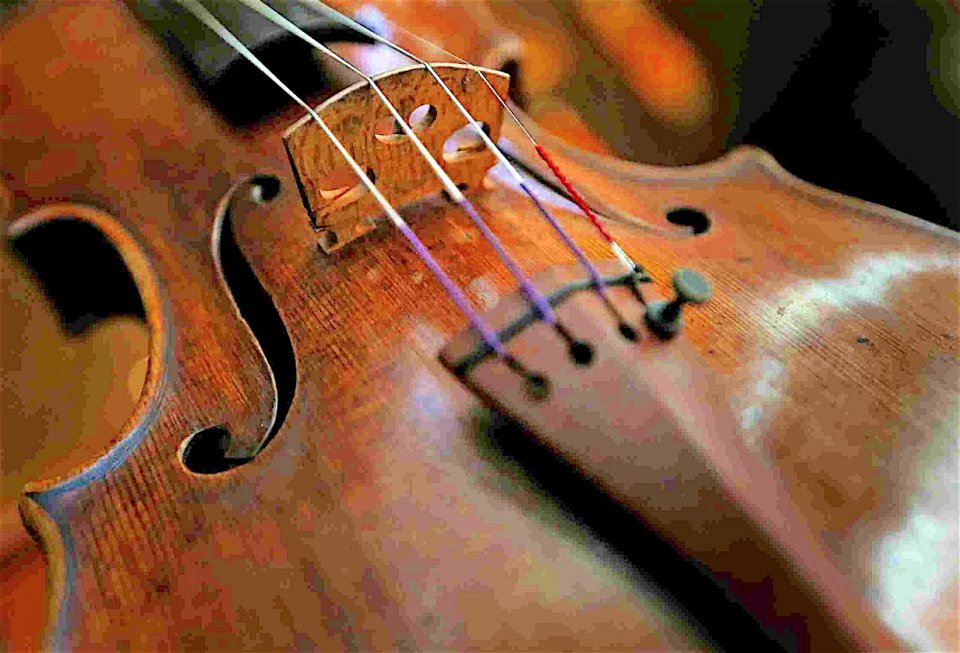

The aim of the project is to develop an industrially producible bio-sourced varnish based on gum rosin and linseed oil, inspired by the ancient know-how of the violin maker Antonio Stradivari (1644-1737). The difficulty is to meet the specifications of an industrial manufacture while achieving high performance of the varnish.

The context is twofold. On the one hand, the need to develop a local resource, the maritime pine resin, which is no longer exploited today, with the desire to participate in the revival of a whole sector in the south-west of France, which goes from the extraction to the development of the resin. On the other hand, the aim is to develop a new biosourced varnish that can be industrialised and thus meet the growing societal demand.

The project was developed from November 2016 to October 2019. The research consisted of drawing inspiration from ancient manufacturing techniques to approach the exceptional quality of Antonio Stradivari's varnish.

The experiments carried out during the Stradivernis project made it possible to identify for the first time the curves of heat treatments on oil and rosin and their influence on the quality of the varnish film, in particular its gloss and resistance to solvents.

The addition of additives considerably improves the drying time of the film and the technical characteristics of the films. The most advanced formulations have made it possible to envisage an extension of this work towards an industrial project. A know-how repository is in progress on these formulations with additives.

The experiments were carried out in three areas:

- Study of oil heat treatments and their influence on the quality of the varnish film. Five treatments were tested: raw oil, two heat treatments below 200°C, rinsing of the oil with water before a heat treatment below 200°C, and standolization at 400°C under nitrogen.

- Heat treatments of rosin and their influence on the quality of the varnish film. Four treatments were tested: raw rosin and three heat treatments at 180°C, 200°C and 250°C for 30 minutes.

- The addition of mineral additives and their influences on the polymerisation and the quality of the varnish film.

Labelled by the competitiveness cluster Xylofutur and financed by the New Aquitaine region and the Landes Departmental Council, the project provided new fundamental knowledge to understand the mechanisms of hardening and quality improvement of rosin-based varnishes.

The project is not yet complete as it requires a development phase for technology transfer to take place.

The Stradivernis collaborative project involved the University of Pau and the Adour region, the City of music (Paris), the University of Créteil, the companies Holiste (Biscarosse), Concept Aquitaine (Bordeaux), Finsa (Morcenx), and the association Api'Up (Capbreton). At present, the objective is to achieve the industrial transfer of the project. To this end, collaboration is underway with the company System Adhesive Assembly Transformation of Aquitaine (SAAT).

Bertrand Charrier bertrand, charrier@univ-pau.fr

Further information

Publications:

Frances, M., Gardere, Y., Duret, E., Leroyer, L., Cabaret, T., Rubini, M., Bikoro Bi Athomo, A., Charrier, B., Effect of heat treatment on maritime pine rosin : Influence on physico-chemical properties and linseed oil – rosin varnishes, soumise à Industrial Crops and Products, 2019.

Cabaret, T., Gardere, Y., Frances, M., Leroyer, L., Charrier, B., Measuring interactions between rosin and turpentine during the drying process for a better understanding of exudation in maritime pine wood used as outdoor siding. Industrial Crops and Products, 130, 325–331, 2019.

National Congresses:

Participation Journées Thèses des Bois, 30 septembre 2019, Québec, Canada (Prix Xylofutur Jean-Claude Pommier Chimie)

GDR3544 science du bois, 20 – 22 novembre 2018, Cluny (Prix du meilleur poster)

ICOME MATERIALS & ENERGY, 30 avril-4 mai 2018, Saint Sebastien, Espagne

GDR3544 sciences du bois, 21-23 novembre 2017, Nantes (Prix du meilleur poster)