Stone pine (Pinus pinea L.) cone harvesting in Portugal continues to occur trough the traditional way, that is, by specialized workers that climb the trees and remove the cones by hand using special tools.

Here we intend to document photographically this traditional knowledge, present the various tools used by cone pickers in the harvesting process and the materials used to build them. This information can be potentialy usefull in other coutries were cone harvesting is made by small, locally operating family firms.

Cone harvesting in Portugal takes place legaly from the months of December to March when the cones reach full size and weight and the pine nuts are completely developed.

The field teams are constituted by the climbers (usualy man) that pick the cones from the trees and operators (usualy women) that colect the felled cones and bag them. Usualy there is a person coordinationg the work.

In an 8-hour working day, a climber is able to pick about 400 kg of cones (fresh weight). It is possible to harvest between 10 and 20 medium-sized trees per day, although this amount depends on the size of the crowns and the number of pine cones in the tree.

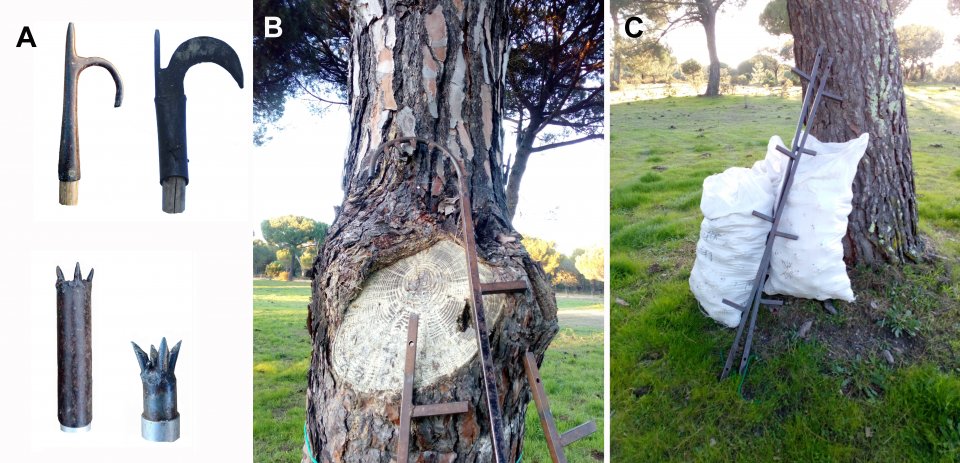

The operator climbs the tree using an adapted ladder, usually made of iron, composed of a central pole to which several steps are connected, also made of iron, arranged perpendicularly and alternately to the central pole (Fig 2). There is the possibility of extending the ladder by adding modules (Fig 1C) that, fitted together extends up to 12 meters in length (Fig 1B). The top of the pole ends with a toothed hook that can be attached to a thick, mechanically stable branch, supporting the entire structure (Fig 1B). A conventional aluminium ladder can also be used but is not common.

During the climb the operator carries to the top of the tree an extendable pole, usually made of aluminium, with a reinforced iron tip in order to hit, pull or push the cone, detaching it from the peduncle (Fig 1A). The material must be strong but extremely light for transportation within and between trees.

Spikes tips poles are preferred in the harvesting that involves climbing the tree. The iron-reinforced tip and the slightly inclined sharp spikes guarantee a better grip to the cone and the break of the peduncule in just one stroke. The hooked tips usually intertwine the inner branches of the canopy making difficult the handling inside the crown. The hook tips are preferred when harvesting from the ground, in small trees with easy access to the canopy.

The difficulty on manually harvesting cones is significantly hampered in taller trees with wide canopies. In some trees this operation is extremely dangerous or even impossible. The personal protection equipment must never be neglected (helmet, gloves and harness). When there is a good production in such trees, the use of a platform lift, for example, can be considered.

The manual harvesting is an activity of high risk for the operator and one of the reasons for the increase of labor costs recorded in recent years. Encouraging training actions, directed towards safety procedures in the handling of harvesting equipment and machines, is fundamental to reduce work accidents.

Apart from the fact that the harvesting is legarly limited in time (winter months), the operational organisation of the teams is complex and often interrupted by weather conditions. The harvesting must be suspended on rainy or foggy days as the trunks tend to be slippery making harvesting additionally dangerous. This creates a discontinuity in wages, discouraging the interest in this activity.

Mechanical harvesting drastically reduces work accidents and the harvesting time. Stand profitability can be significantly higher in optimal conditions. The silviculture used in stands where mechanical or manual harvesting is going to be applied is different. A cost–benefit analysis and all silviculture interventions should be decided at young ages, namely the choice of tree density, the intensity and frequency of thinnings and pruning in order to obtain clean stems for the use of the mechanical tree shakers.

Alexandra Correia, alexandrac@isa.ulisboa.pt, https://alexandracorreia.wixsite.com/curriculum

Further information

Estudo sobre a cadeia de valor da fileira Pinha/Pinhão (Pinus pinea L.), Edição: UNAC – União da Floresta Mediterrânica, Autor: Agri-Ciência – Consultores de Engenharia, Lda. (2014). http://www.unac.pt/index.php/documentos/publicacoes/45-cadeia-de-valor-da-fileira-da-pinha-pinhao/file

This factsheet was developed under the operational groups:

FERTIPINEA – Nutrição e fertilização do pinheiro manso em sequeiro e regadio

+Pinhão – Gestão integrada de agentes bióticos associados à perda de produção de pinhão

Financed by PDR2020 (Programa de Desenvolvimento Rural 2014-2020); Parceria n.º 52/ Iniciativa n.º 81, Ação 1.1 Grupos Operacionais promovida pelo PDR2020 e cofinanciada pelo FEADER, no âmbito do Portugal 2020.

Alexandra Correia

Alexandra Correia